Cleveland Roller Mill Museum Tours

Cleveland Roller Mill Museum’s current exhibitions

run from Memorial Day weekend through November 01, 2026.

Open on weekends only, 10am to 4pm.

Admissions: Adults: $10.00, Ages: 13 - 17 $7.00, Children: free accompanied by an adult.

Mill History

"Valley of the Mills" This Exhibit provides information on the mill's history, and wheat farming and milling in Mora County, as well as a historical overview of the history of western Mora County. Wheat farming and milling were Mora County’s most important economic enterprises for nearly a century encompassing a time period from 1860 to1940.

Three Story Mill

The Cleveland Roller Mill Museum is a three story, adobe, water powered flour mill that has been turned into a local history museum. The Mill's original equipment is intact and operable for demonstration purposes.

Plan Your Visit

Plan your trip to the Cleveland Roller Mill Museum. We offer tours for visitors of all ages. Explore the unique adobe architecture of Mill Museum's building, which blends in the surrounding landscape and provide a stunning backdrop for our exhibits.

Our Mission

The Historic More Valley Foundation is registered as a non-profit organization with the IRS as a 501-c-3 organization. Its mission is to preserve and operate the Cleveland Roller Mill Museum and its history. The museum was founded in 1989.

Mill Videos

Video by Richard Gonzales. Click on link below.

Mill Machinery in Operation.

The Mill machinery runs only on Labor Day weekend. This coming August 30 - 31, 2025 is when it will be in full operation again.

The Workings of The Mill

Water Wheel

When visitors drive up to the museum, there is no visual evidence of a water wheel at first glance. Out of sight, and on the east corner of the building is an 18 foot, 6 inch massive cast iron wheel, originally purchased in the late 1800s. Water once continually flowed over the massive wheel to power the original machines inside the Mill.

Main Gear

The main gear inside the mill is attached to the water wheel and provides power for numerous pulleys and belts that drove the mill's machinery. This gear is taller than the average person and is made of cast iron. When the mill was built at the end of the 19th century the machines, gears and other equipment was brought into Las Vegas, New Mexico by train, then transported by wagon to the mill site in the Mora Valley. Today, a trip between these places is only about thirty minutes, back then the journey by wagon took all day.

Cold Steel Milling

In the beginning of flour milling, two stones were used to crush grain. In the latter part of the 1800s the technology of cold steel made it possible to develop rolls that would accomplish the task in a much more efficient manner. This roll stand contains two sets of rolls, and the mill has a total of four roll stands.

%2003.jpg/:/cr=t:12.42%25,l:0%25,w:100%25,h:75.16%25/rs=w:600,h:600,cg:true)

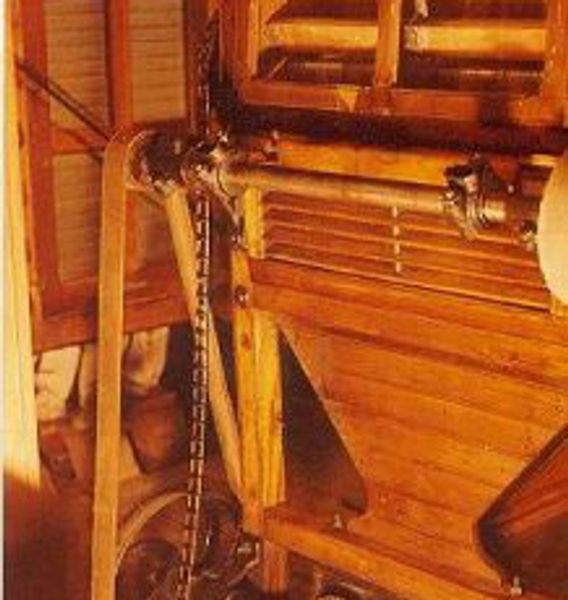

Gravity Chutes

The wheat seeds would begin the grinding process by going through the first of the roller mill stands (right). This mill stand contained the "break" rolls (very rough) that would start the grinding process by "breaking" the bran outer hull of the wheat. Subsequent smoother rolls would continue the grinding until all possible flour, bran, and germ was extracted. The long vertical wooden items in the foreground are gravity chutes, part of the semi-automatic transport system used to move wheat and flour around the mill. Elevators consisting of continuous looped belts with small buckets would dump the product into the gravity chute where it would slide down to the next machine, or bin.

Box Sifters

The box like object in the background is one of the huge sifters of the "four box sifter," and contains large horizontal screens from top to bottom. The boxes are suspended from an eccentric shaft. The motion of the shaft when operating causes the boxes to shake and sift flour through their screens. The lower half of each box contains controls to allow flour to cross the screens or bypass them in order to process the specific grade of flour the miller wanted. The machine in the foreground is a "plan sifter" which, besides sifting also contains a fan to blow off fine dust. Some of the original belts used to run the mills machines were made of leather and the museum still maintains those leather belts that were left on the machines when the mill ceased operating.

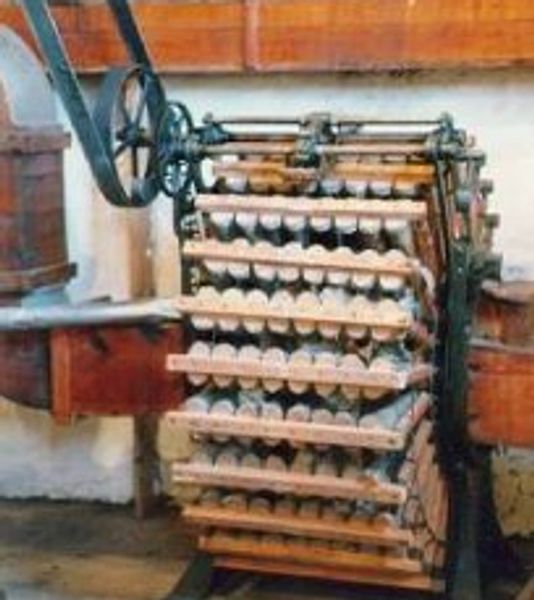

Sock Duster

This strange looking machine called a sock duster had only one duty; to collect dust. Fine dust from flour milling can be very hazardous not only to the health of people breathing it (it was common for early millers to have lung congestion) but also because in quantity, dust is a deadly explosive. Attached to the horizontal piece of wood on each row was a series of eight cone shaped socks. Dust was blown into the machine by the two shafts, one on each side of the duster, and the small metal pipe on the left. The dust would be trapped in the socks and then later extracted in bulk and removed.

Roller Mill

This is one the four flour roller machines that is located on the main floor of the Mill.